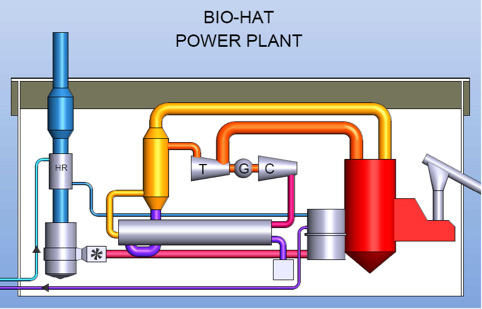

BioHAT® Power Plant is a new generation small-scale power plant that uses biofuel. Airia has patented this process. It is base on an externally fired gas turbine cycle where heat and gas is transferred to the working gas via heat exchanger. In the design and optimization of the process well-known methods from pulp and paper industry have been applied. In BioHAT®, the temperature of the working gas entering the turbine remains lower than with the conventional gas turbines. The resulting loss of power and efficiency is compensated by introducing water into the cycle in a novel way. The current steam injected applications use only the sensible heat from the turbine discharge flow to generate steam. Instead, Airia has developed a heat exchanger that utilized addionally the latent heat of the steam to evaporate water. This results in increased amount of water in the cycle and consequently, increases electric power output and efficiency. The BioHAT® concept enables power generation efficiencies up to 40%.

Components

Power production

Power is generated using modified gas turbines from aviation industry.

Boiler unit

Heat energy is produced in modified bio-fuel boiler unit where the superheater provides energy to the power production gas.

Heat exchanger unit

After the compressor the water evaporation is taken place by condensate of the water steam in gas turbine exhaust flow and also by cooling the flow from the compressor.

LUVO

Air to superheater is heated with the exhaust gas after the turbine.

Heat Recovery – Ventur

Efficiency and emission c ontrol is secured with specially patented ventur that provides clean and recovered heat.

BioHAT® PLATFORM

Market area

BioHAT® plan t market area can be divided to two. First we have the traditional places where Combined Heat & Power plant are and local bio-fuel is available. Heat recovery can be replaced with absorption method based on cooling system. This is provided to the developing markets and especially warmer areas around the globe.

Capacity

Airia is pre engineered 300 kW,e and 1500 kW,e systems to the markets. Technology is profitable up to 5 Mw,e.

Size

Smaller 300 kW,e plant is delivered to the site in four container. Modules are pre assembled and the joint fitted on site.